You can implode different item types to see which BOMs use the items.

The default implosion settings are to implode multiple stock items for all parents in the hierarchy. If you select BOM records in the Bill of Materials List and click Implosion in the toolbar, stock items for the selected BOMs are imploded for all parents in the hierarchy.

If you choose Implosion from the Enquiries menu you can select an Item Type to implode. For example, you can see where labour resource groups are used in BOMs.

You can also choose which parts of the BOM hierarchy to show in the implosion, using the Parents selection box. For example, if you want to see where a wheel rim occurs in your BOM hierarchies, you can choose from the following Parents selection options.

| Parents selection | What assemblies are shown |

|---|---|

|

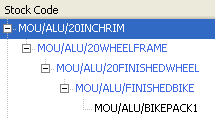

All Parents In Hierarchy |

This is the default selection. The item is listed and all top level and sub-assemblies containing the item are shown when you expand the item details.

|

|

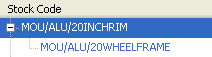

Immediate Parents Only |

The item is listed and only sub-assemblies containing the item are shown when you expand the item details.

|

|

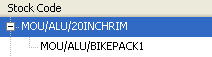

Top Level Parents Only |

The item is listed and only top level item assemblies containing the item are shown.

|

|

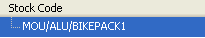

Consolidated Top Level Parents Only |

Only a list of top level item assemblies containing the item is shown.

|