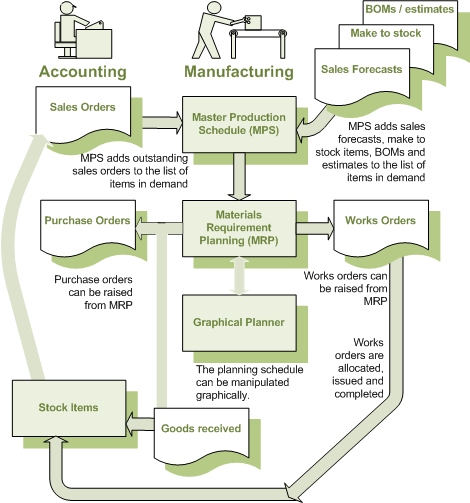

BOMA stock assembly and process costing system, which provides facilities to specify the structure of finished items in terms of sub-assemblies and components.s (bill of materials), estimatesForecast project costs, based on expected costs of labour, machinery and operation times. In Manufacturing, estimates are produced for one-off items or non-repetitive batches., sales forecastsThe best estimate of future requirements. This is used as input to the MPS (Master Production Schedule). Forecast orders received should be subtracted from the forecast to leave a residual forecast in the master schedule. Total demands can then be calculated as orders plus residual forecast for each time period., items to make for stock and sales orders are all added to the list of items in demand in the MPSMaster Production Schedule (MPS). The planning of production (usually end item production), to satisfy current and forecast sales orders. The sum of MPS items must equal the agreed sales and operations plan for the items over each planning period. Planning periods are normally a month or a four week period. Items planned within MPS are exploded by MRP (Materials Requirements Planning) to produce the material and capacity requirements. module.

From the Master Production Schedule list a Material Requirements Planning schedule is generated which recommends purchase orders or works orders be created to fulfil the demand. The schedule can be manipulated graphically in Graphical Planner.

You can plan and shift resources, using Graphical Planner. This will help you to deliver the stock you need to fulfil your sales orders.

Graphical Planner does not need to be installed onto every machine that is running Manufacturing, but it must be installed on every machine which will require access to it.

Note: For every machine that requires access, it is necessary to register and activate Graphical Planner individually. Registration is only done online, so a connection from the software to the Internet is required.

Information on installing and registering Graphical Planner is provided in the Sage 200 On Premise Deployment and Installation Guide.

When goods are received they are placed in stock and this allows fulfilment of sales orders.