Orders placed with your suppliers are contractual agreements between you, the customer and the supplier about delivering products or providing a service on time and at an agreed price.

Strong order management allows you to maintain order visibility throughout the life cycle of an order from demand creation to supply fulfilment.

|

|

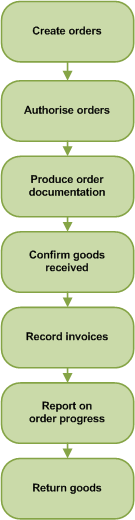

Create orders

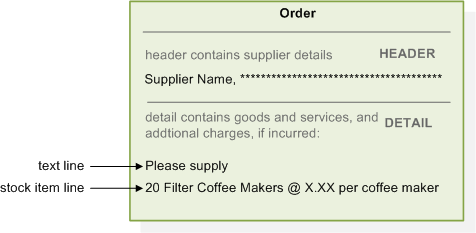

Record orders you want your supplier to fulfil. There are two methods to choose from. You can:

Authorise orders

Order authorisation is optional. You can set up rules to select which orders require authorisation, based on their value and who has placed the order. Produce order documentation

You can print orders. Copy purchase orders can also be printed for office use if required. Confirm goods received

Record delivery of goods, where the goods received are matched to the purchase order. You can also include recording services that have been satisfactorily completed. Record invoices

You can match the invoice to the purchase order or the record of goods received. Those with discrepancies can be marked as disputed provided you set the system to use disputed invoice processing. This stops the invoice being processed further until the dispute is removed or the disputed value can be written off. Monitor order progress

Interrogating your Purchase Order Processing system is important at all stages of the order life cycle to monitor order progress. Return goods

Sometimes goods are returned, and dealing with returns is another stage in the order life cycle. The goods are recorded as returned and then despatched. On receipt of the supplier's credit note the information is matched against the goods returned record. Depending on how you set up your system you may not need to complete all of these stages; e.g. order authorisation. |